How to Determine the Size of Lathe Machine

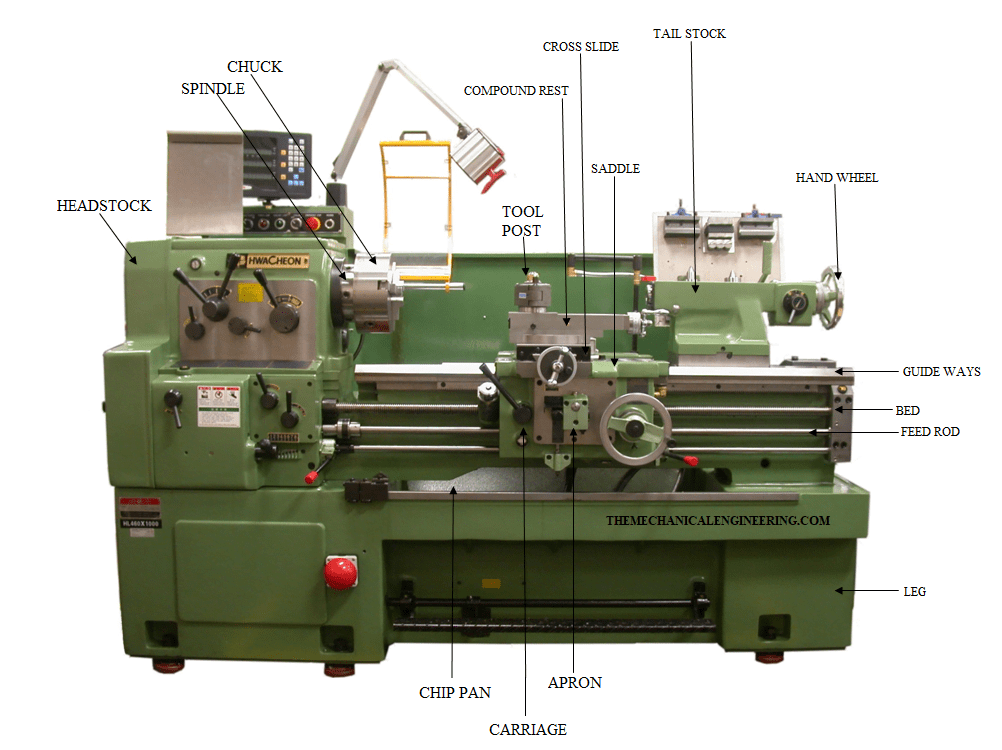

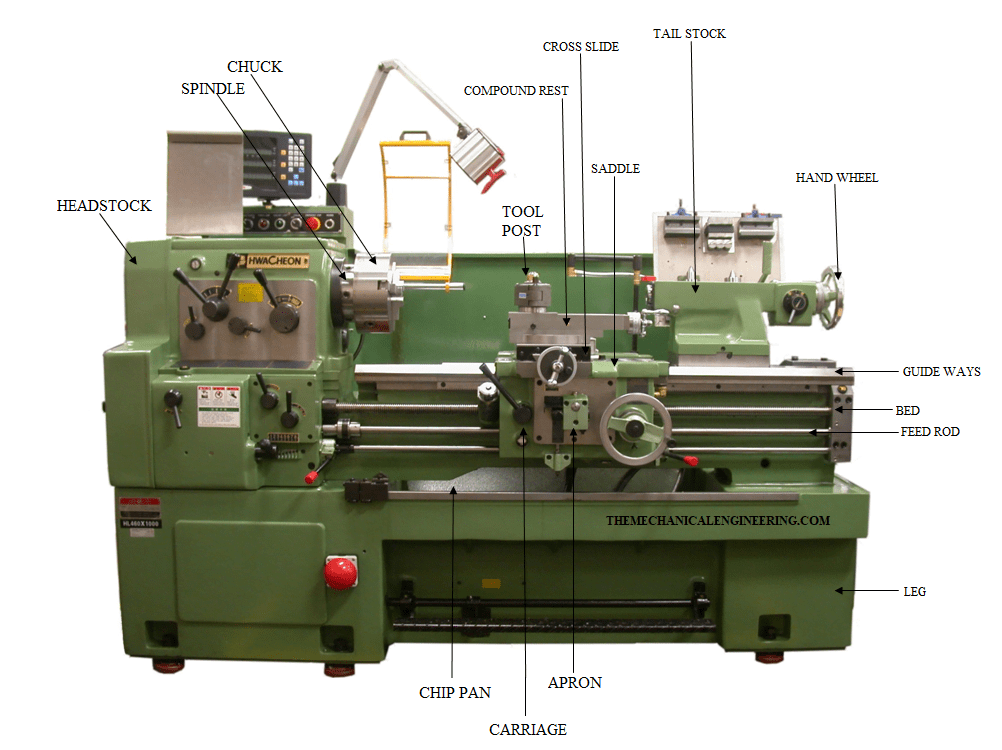

Draw a neat sketch and identify the parts of lathe machine. Size of a lathe is specified in any one of the following ways.

Pin By Wolfgang Heinz N On Tool Lathe Machine Parts Lathe Machine Lathe

Cutting edge angles generally range between 60 and 65 for workpieces cut in the middle.

. It removes a small amount of material from the object. Ad We have many lathe options to choose from all with durable cast bases. In order to prevent errors the cutting edge angle must be 90 degrees.

Where d - is the diameter of the work in inches and. Designed in the USA. Knurling is precessed on a which is performed on a lathe machine.

On the head stock spindle and or tail stock ram of the lathe. A linear scales usually uses on robotics machine tools pick-and-place PCB assembly equipment semiconductors handling and test equipment. The distance from the center of the spindle to the surface of the bed tells you what the maximum diameter limit is.

Depending on your need you can find 45-70 and 70-90 as the cutting edge angles. 10Draw the tool shapes which are used on lathe machine. The chuck is the circular metal object that spins to shape the.

How to measure the size of a lathe machine. However there are some lathes that will allow for either one of two Tool Post sizes. The chuck is the circular metal object that spins to shape the material.

Lead screw gear 12x3 36 teeth. Measure the distance in inches from the center of the chuck to the nearest point on the bed. If not listed look in your manual or sales literature to find the thread size.

Stud gear 8x324 teeth. If you measure 6 then you have a 12 swing lathe. You can determine its size by the size of its tail stock.

12Sketch and indicate Angles and Parts of lathe cutter. While some lathes operate at a single speed many will have multiple speed settings. Again while there are several alternative ways to measure travel the safest way to protect your equipment is to physically measure the travel of your machine.

How to Determine a Lathe Size Step 1. Measure the distance in inches from the center of the chuck to the nearest point on the bed. Quick Shipping Easy Online Ordering.

On some lathe swing sizes there might be an overlap in the Tool Post sizes allowing for either one of two different size Tool Posts. For this knurling tool is used which is also known as Knurl. Where d - is the diameter of the work in mm.

Hold a ruler marked with millimeters across the end of the tail stocks opening. Because change gears of various sizes are used the distance between gears will vary. This is the largest diameter of work that will revolve over the lathe saddle or.

Locate the hole in the center of the chuck. The tool which is used in reaming preocess is called Reamer. In the British system cutting speed is expressed in feet per minute and diameter of the work in inches.

Because these gears are impossible multiply each by a common number to obtain the desired gears available in the change-gear set as follows. Most lathes use the same MT in both the head stock and tail stock. I The height of the centres measured over the lathe bed or ii Swing or maximum diameter that can be rotated over the bed ways or iii Swing or diameter over carriage.

A 3 x 15 lathe can easily weigh more than 30 kg. How to Determine a Lathe Size. Remove the Morse taper from the lathe by firmly pulling it from its holder.

If you have a lathe and want to measure for the swing you simply measure from the bed of the lathe to the center of the spindle and then double that measurement. Measure the distance between both ends of the center of the chuck. We measure the cutting tool diameter or the part diameter on the lathe in inches along with the 3-inch diameter.

Measure the distance in inches from the center of the chuck to the nearest point on the bed. Locate the hole in the center of the chuck. If listed make a note of the SKU______ example IDNS IENS etc 2.

The size of the lathe is determined by two factors. As a constant its based on an abstract simplifica-tion namely rpm rpm 12 diameter. The distance from the end of the spindle to the inside end of the tailstock tells.

What Is The Cutting Angle Of Lathe Tool. There are a couple of ways to determine which size scales you need. The Lathe Swing is the primary determining factor in selecting the correct Tool Post.

Locate the hole in the center of the chuck. 13What are the types of work holding used on a lathe machine. Machine model thread size if known.

Refer to the insertadaptor chart below to see if your lathe is listed. But milling machine lathe machine can use bigger size ones. To make the drilled holes in perfect size on an object the reaming preocess is performed.

2 Motion control systems Servo controlled motion systems use linear scales to provide accurate high-speed movement. Ad Expert Support Engineers. Make a note of these.

14Calculate the time required to make a roughing cut of a 12 in. N - is the rpm of the work. A lathe double that size would weigh far more and require an engine lift or small crane to move into place.

How do you specify lathe size. Measure the distance between both ends of the center of the chuck. In a lathe it is the peripherical speed of the work past the cutting tool expressed in meters per minute.

Size of a Lathe. The best way is to physically measure the travel of your machine as shown in the photos below. Power One of the last things youll need to consider when buying a new lathe is the motor.

Over 40 Years Of Quality Value Service. However some lathes will use one size of MT in the head stock and another size MT for the tail stock so be sure to check both in order to get the right MT size accessories you need for your lathe.

Lathe Machine Definition Parts Types Operation Specification Advantages Application Notes Pdf

How To Use A Metal Lathe Gap Bed Lathe Machine Operations Tsinfa

Lathe Machine Has Been Divided Into Three Main Sections See Online Download Scientific Diagram

Comments

Post a Comment